Ines Rivelli and Dr. Phil Cardoso

July, 2015

Last summer, the Dairy Focus Team visited 20 dairy farms in Illinois. One of the objectives of these visits was to investigate the association between bedding material and milk quality in dairy farms. Usually, two main types of bedding are available for dairy farmers: 1) organic bedding: wood shavings, sawdust, manure solids, and straw; and 2) inorganic bedding: sand and mattress. It is important to choose a material that provides a clean and comfortable surface for the cow to lie down while still being economical. The type, amount, percentage of dry matter (DM), and percentage of organic matter (OM) in the bedding can influence dairy cows’ lying behavior and performance. Failure to maintain adequate amount of bedding will result in stalls that are not comfortable, and that can result in hock injuries (bald spots) as well as sole ulcers caused by prolonged time standing.

Nowadays, compost bedding is becoming more popular in dairy farms. It can provide a clean and dry surface for cows to lie down. This type of bedding may have a lower initial capital cost when compared with other types of bedding like sand, but the annual cost of the material and maintenance have to be considered. Compost bedding needs to have more bedding periodically added in order to keep a clean and dry surface. Composting is an aerobic (with air) process in which microorganisms consume oxygen and produce carbon dioxide, moisture, and heat. The effectiveness of composting depends on the maintaining the proper temperature as well as the proper proportions of oxygen and moisture. The microorganism can take the carbon, nitrogen and moisture necessary for composting from cows’ feces. The temperatures generated by microorganisms are between 120oF and 130oF, and it is important to keep in this range to inactivate viruses and pathogens and allow for good composting. The bedded area should be aerated to a depth of 7.1 to 9.4 inches at least two times a day to provide a dry surface for the cows when they come back from the parlor. Ideally, moisture of the pack should be kept in a range of 40 to 65%. When moisture is less than 40%, the temperature will be too low and the rate of composting will be slower because microbial activity will be reduced. If bedding moisture is getting too high (too much water), clean bedding should be added to allow for ideal bacterial growth and to maintain the bedding surface. Every 0.4 inches less bedding can reduce cows’ lying time by approximately 10 minutes per day.

Though compost is becoming more common, sand is still the most popular bedding type. Over time, bedding quality decreases as it becomes contaminated with urine, milk, and feces. This is associated with an increase in OM and decrease in DM. Cows should be bedded with sand with less than 3% OM and more than 95% DM. Dairy cows prefer bedding with softer surfaces and will lie longer when they are deep bedded. One of the advantages of “deep bedded” stalls (5.9-7.9 inches on top the stall base) is that cows can drag sand contaminated with manure and other waste material out of the stall on a daily basis. In order to maintain a clean and comfortable bedded stall, sand must be refilled with additional sand to keep the curb from protruding. There is a subjective test called “the knee test” that can give us an idea of how comfortable the bedding is. If after kneeling on your knees on the bed for 10 seconds your knees get wet and you don’t feel comfortable, then your stalls probably can use some improvement in bedding management. It is also recommended to perform a second test by dropping quickly to the knees from a standing position. If the impact feels comfortable, it is also comfortable for the cows.

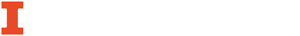

Manure handling and stall design are some of the biggest challenges in bedding systems. When manure is mixed with sand it can be challenging to clean barns; so the barn set-up, the alley floors, and manure-handling systems should be adapted to solve this issue. A proper neck rail location will prevent the presence of urine or manure in the bed. An ideal position of the neck rail is 64 to 72 inches forward from the rear curb. A brisket board can restrict the forward location of a cow lying in the stall. Ideally, the brisket board is less than 2 inches away from the neck rail. During our visits we found that 16 farms (80%) had a sand bedding system; approximately 32% of those farms had a combination of sand and different type of bedding such as straw or compost. Among the other 4 farms, 2 farms (10%) had straw bedding, 1 farm (5%) had sawdust, and 1 farm (5%) had their cows on pasture. Bedding samples were taken from different spots located in lactating and dry cow stalls. Dry matter analysis was performed in all types of bedding, and OM analysis only in sand bedded stalls. On average, the 12 farms that used sand as bedding had 92 ± 8% DM, 3 ± 2.7 % OM, and tank somatic cell count (SCC) average of 204,000 ± 91,000 cells/mL. As OM in bedding increased, the SCC also increased (Figure 1).

Organic Matter, %

Organic Matter, %

Figure 1. Linear correlation between somatic cell count (SCC) and organic matter. Each dot represents one farm.

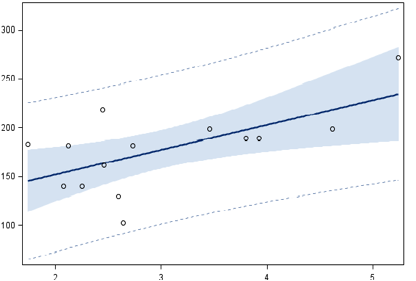

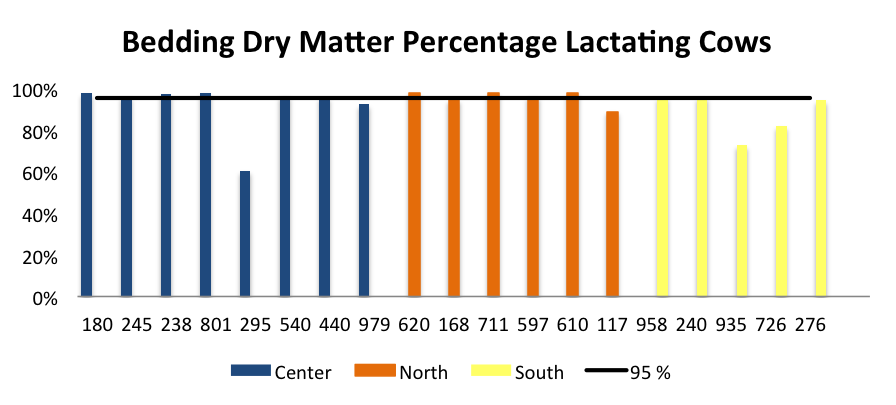

Figure 2 shows that there are only a few farms in which bedding materials for the lactating cows are below the ideal 95% dry matter line. In Figure 3, we can see that there are some farms in which the organic matter percentage of the bedding is above 3%.

Figure 2. The black line represents a 95% dry matter.

Figure 2. The black line represents a 95% dry matter.

Figure 3. The black line represents a 3% organic matter percentage.

Figure 3. The black line represents a 3% organic matter percentage.

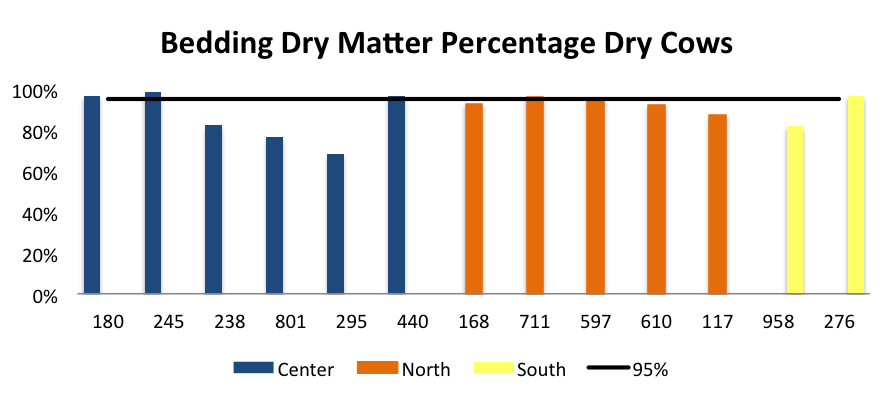

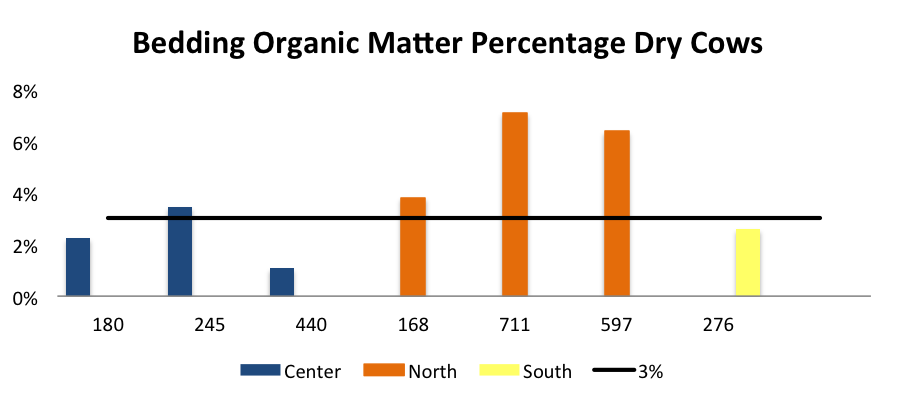

Figures 4 and 5 show the results for bedding material for dry cows, which are similar to the ones showed for lactating cows.

Figure 4. The black line represents a 95% dry matter percentage.

Figure 4. The black line represents a 95% dry matter percentage.

Figure 5. The black line represents a 3% organic matter percentage.

Figure 5. The black line represents a 3% organic matter percentage.

Remember that bedding quality is associated with the ability of the animals to express natural behavior, and with milk production and quality. High SCC is associated with low milk production and higher risk for mastitis. It is important that dairy farmers know the quality of the bedding material used in their operations and that their management allows for OM less than 3% and DM greater than 95%.