Dr. Phil Cardoso

September 2023

On July 17, the University of Illinois and the Illinois Milk Producers’ Association held the 2023 Dairy Technology Tour at WILRA Farms in Nashville, IL. On-farm tour highlights included the Waikato rotary milking parlor, the automated ventilation system, and an opportunity to meet the calves. Over 160 people attended the field day, and we had good discussions. A three-minute snapshot from the event is available at the IMPA website (https://www.illinoismilk.org/2023_dtt).

The tour’s goal was to bring information to dairy farmers in Illinois regarding new technologies that allow for improved cow comfort and improved efficiency. I have selected a few take-home messages from the tour to share with you, and I hope you find this information helpful. Stay safe, and feel free to reach out if you have any questions.

I would like to thank the Harre family one more time for hosting the event and for positively impacting the dairy industry in Illinois.

Innovative technology at WILRA Farms

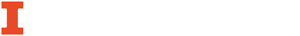

The Harres’ new barn has a very innovative ventilation system (Figure 1). The positive pressure, or all-seasons hybrid, ventilation was developed by Dr. Gordie Jones. In this system, the barn is positively ventilated for part of the year and naturally ventilated the rest of the year. The temperature fluctuation throughout the year is easily adjusted with this ventilation concept. During the tour, we witnessed that it didn’t matter where you were in the barn; every cow had equally fresh air. The ventilation equipment in the barn is adjusted in three different states according to the temperatures: warm weather, when the temperature reaches above 66 degrees Fahrenheit, mild weather (between 23 degrees to 66 degrees Fahrenheit), and cold weather (lower than 23 degrees Fahrenheit).

Figure 1. WILRA Farms’ new barn with an all-seasons hybrid ventilation system.

Positive pressure is used when the temperature reaches higher than 66 degrees Fahrenheit. In these temperature conditions, recirculation fans installed at tilt position on both sidewall lengths are turned on over the free stalls. Meanwhile, all the curtains on the sidewalls are closed. With this setup, the fans push fresh air and cool down the cows while they rest in their beds. Natural ventilation is used during mild weather; the sidewall curtains are partially closed to fully open, and no recirculation fans are turned on. The ceiling fans can operate on demand when there is a need to have the air mixed downwards and to warm up the building at cow level. During cold weather, the curtains on the sidewalls are partially open, and the opening is adjusted according to the weather outside. In this configuration, some fresh air is still allowed to enter the barn. The curtain on the ridge is partially open, allowing warm air and moisture to escape. Both the curtains on the roof and the sidewall curtains are regulated to provide four continuous air exchanges per hour. Each farm may have a different setting for the curtains and fans. The adjustments are all automatic, and Nick Harre explained the different electronic settings used to get the best ventilation in the barn. The new hybrid barn also features a flush system that recycles water, manure, and sand bedding in the barn.

Figure 2. 2023 Dairy Technology Tour participants learning how the 44-cow rotatory parlor from Waikato is used at WILRA Farms.

The new milking parlor (Figure 2) started operating in December 2021. During the tour, Clint Harre explained how they milk 230 cows per hour with two people in the parlor. It is a Waikato rotatory parlor with 44 stalls. The farm is milking 500 cows three times a day with a herd milk average of 98 pounds per cow per day. The parlor connects with PCDART and can alert the milkers through speakers about activities to be performed on the cows, like special treatments. At the side of the parlor is a lovely screen where real-time information from all the cows being milked is displayed. This information includes what is going on in the parlor, the cow’s number, what group she’s in, average volume, and trend in volume. The parlor also has conductivity meters that provide real-time readings and can be used to indicate health issues such as early-onset mastitis. With the new parlor, because the milking procedure is quicker, there is more time for the cows to spend at the barn.

“I did the math a month or so ago,” Harre said. “A cow’s lactation is usually 305 days. During one lactation, in the new setup, these cows spend almost 30 more days in the barn. They walk 35 fewer miles. From the old barn to the old parlor might not seem like a lot, but when you are talking three times a day, over 305 days, they have 30 more days in the barn with food, drink, company, and bedding.

WILRA Farms is well positioned to expand their herd if they choose to.